Dear readers,

High-quality welds demand routine and experience in using the welding torch. If you don’t feel comfortable relying on this alone, comprehensive welding data documentation is a similarly indispensable way of checking and validating the quality of individual welds, which is precisely what more and more customers are now demanding.

Fronius Easy Documentation provides the perfect answer, offering every user a new and especially user-friendly way of recording welding data.

Take a look at our current application story to see how simple it is. This story explains how a steel carport was welded together with the assistance of Easy Documentation. If you’re still not convinced, our website contains a wealth of additional information on the subject. In addition, our latest How-to video provides clear step-by-step instructions.

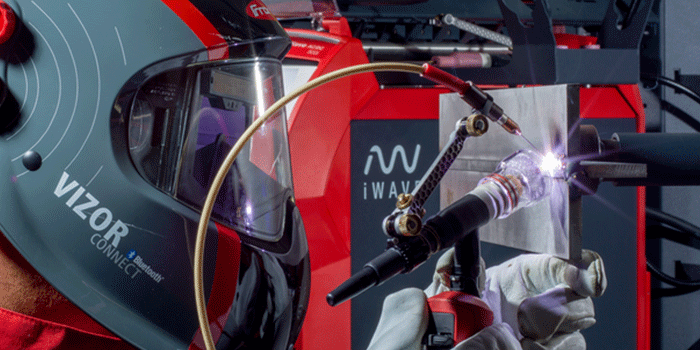

The new Fronius TIG DynamicWire Welding Package also promises greater ease of use. An automatically adjusted wirefeeder renders obsolete the two-handed dexterity that was previously required during cold wire TIG welding. This latest Fronius innovation will allow you to once more devote all your attention to creating the perfect weld. You can find out how by visiting our product page, where a video will demonstrate exactly how it works.

Happy reading!

Your Fronius Weld Informed Team