Weld Informed: Fascination Welding!

| |

|

/ Perfect Welding / Solar Energy / Perfect Charging

|

|

| |

|

|

| |

WELD INFORMED

|

|

| |

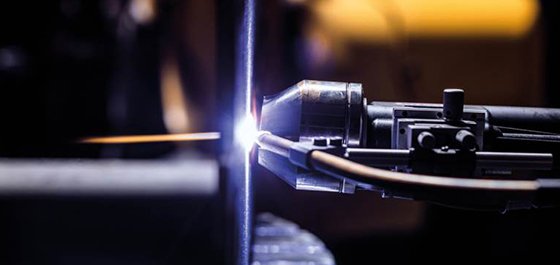

TIG welding with ArcTig

|

|

|

| |

|

|

|

|

| |

Dear readers,

We have started the new year feeling well-rested and rejuvenated and are raring to go! We hope 2021 only has the best in store for you too. When it comes to arc technology and efficiency, we can certainly help:

In our current hot topic article, ArcTig, you can find out about how speed can be optimized during TIG welding and how to obtain high-quality weld seams at the same time.

You can also read about the basis for keyhole welding and the challenges faced when welding in the food industry. We are also ensuring greater efficiency in other industries, for example through the use of the ArcRover 22 welding carriage. You can find out more in the Aumayr customer story.

Happy reading,

Your Fronius Weld Informed Team

|

|

|

|

| |

|

Hot topic: TIG welding with ArcTig

|

| |

|

High weld seam quality is a key criterion in TIG welding. Efficiency and speed are also playing an increasingly important role, however. With ArcTig, these factors are no longer a contradiction: among other things, the process can reduce the amount of preparatory work and rework. Find out more about the benefits.

|

| |

|

Find out more about ArcTig

|

|

|

|

|

|

|

| |

|

Keyhole welding

|

| |

|

From the food industry to the aerospace industry: when weld seams of the highest quality are required, many companies rely on TIG welding. In terms of speed, however, compromises usually need to be made. By contrast, single-pass keyhole welding based on the TIG process allows for perfect seams in a shorter time.

|

| |

|

|

|

| |

|

Food industry

|

| |

When it comes to welding in the food industry, it’s all about hygiene. Germs and bacteria have no place in this industry.

For this reason, surfaces and welded joints must be as smooth and as flat as possible and must not exhibit any spatter or temper coloration. Find out which welding processes Fronius has to offer for this purpose.

|

| |

|

|

|

|

|

|

| |

|

Customer story: Aumayr GmbH

|

| |

|

With sites in Austria and the Czech Republic, Aumayr GmbH produces ventilation ducting systems that are tailored to customer requirements. By using the ArcRover 22, the company has been able to significantly optimize both welding quality and production times. “Investing in the ArcRover 22 was absolutely the right decision,” explains Erwin Kunst, Head of Metalworking.

|

| |

|

Read the Aumayr customer story

|

|

|

|

|

|

|

© 2020 Fronius International GmbH

|

|

|

![]()