Weld Informed: Fascination Welding!

| |

|

/ Perfect Welding / Solar Energy / Perfect Charging

|

|

| |

|

|

| |

WELD INFORMED

|

|

| |

Save Time and Money with WeldCube

|

|

|

| |

|

|

|

|

| |

Dear reader,

Every second saved in the production process is crucial, especially when large unit numbers are involved; errors and malfunctions lead to downtimes and result in high costs. Data management systems such as WeldCube Premium – today’s hot topic – enable welding production processes to be monitored and optimized. In this edition we will be looking in particular at welding processes and solutions for the production industry.

Your Fronius Weld Informed Team

|

|

|

|

| |

|

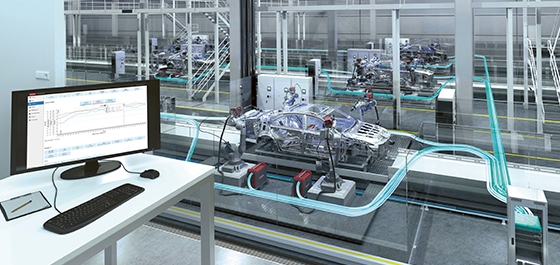

Hot Topic: WeldCube Premium

|

| |

|

Which component has been fabricated in which way? Are the tolerances correct? WeldCube Premium makes it possible to determine these parameters in detail, the importance of which has been proven when it comes to compliance with the strict legislation that exists in many industries. The recording, storing, and processing of welding data helps to ensure optimum component quality and to identify errors immediately.

|

| |

|

Find out more about the functions of WeldCube

|

|

|

|

|

|

|

| |

|

Customer Story: Rosenbauer

|

| |

|

Quick and reliable service: Rosenbauer International AG is the world’s largest manufacturer of fire-fighting vehicles and fire-fighting equipment. Limited space, complex components, the increased use of aluminum and stainless steel, and high cost pressures are among the welding challenges faced. You can read about why Rosenbauer relies on the TPS/i welding system from Fronius in its production processes in our reference article.

|

| |

|

Read the full Rosenbauer story

|

|

|

|

|

|

| |

|

| |

|

Safe and Demonstrable Welding

|

| |

|

From car bodywork to railroad bridges: wherever welding is carried out, manufacturers and users expect flawless quality. You can find out how data management improves quality assurance in our blog.

|

| |

|

|

| |

| |

|

| |

|

A New Level in Welding Technology

|

| |

|

Total control: the number of individual droplets and the pause time between cycles can be set with the CMT Cycle Step process variant. The result is a flawless weld seam appearance and absolute reproducibility.

|

| |

|

More about CMT Cycle Step

|

|

|

| |

|

|

|

|

| |

|

Pinpoint Accuracy with DeltaSpot

|

| |

|

When it comes to joining aluminum plates and sheets, resistance spot welding is the main method of choice, be it in the automotive industry or in the manufacture of fridges and washing machines. With DeltaSpot, up to 7,000 spatter-free welding spots can be produced without any interruption.

|

| |

|

Find out more about the advantages of DeltaSpot

|

|

|

|

|

|

|

© 2018 Fronius International GmbH

|

|

|

![]()